An important question those involved in swine production must ask of themselves is, “what exactly am I producing?” The purpose of this question is to move from thinking of production in simple terms, such as marketing pigs with some average characteristics, towards thinking about the value that is created or lost with each pig individually.

At weaning, some pigs fall below acceptable weights and are heavily discounted or even condemned. At finishing, because pigs are different weights and have different fat compositions the base price is adjusted by the processor. However, if production is only thought of in simple terms, these realities are overlooked. Instead, we must begin to consider whether the pigs we produce are what we intended, pigs that achieve their maximum value.

In general terms, precision agriculture is the practice of using fewer resources by delivering them only to where they have the greatest impact. This efficient use of resources and emphasis on output ultimately leads to new, higher levels of average profitability.

In the case of crop production, precision agriculture is made possible largely due to available technologies. In the case of swine production, precision agriculture is primarily a data driven process to identify individual pig performance and then to describe how the inputs lead to that outcome so the production process can be adjusted to improve output.

Mass Marketing Farm stakeholders that decide to adopt precision agriculture practices and methods must first realize that it is not a single event that once achieved brings it to a conclusion.

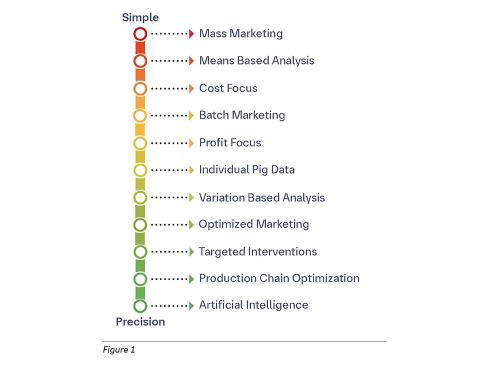

Figure 1 illustrates how a farm might proceed from simple production practices to precision ones over time.

Rather, it is a long-term process of adopting new methods and practices. The first step in this process is a focus on profit as being the most important variable in determining farm performance. While certain sub-systems on a farm might be focused on other variables such as cost or a production metric, these sub‑systems must be guided by higher levels of production that are profit oriented. This will ensure that the farm is not being trapped at lower average profits because efforts are put into improving a sub-optimal variable.

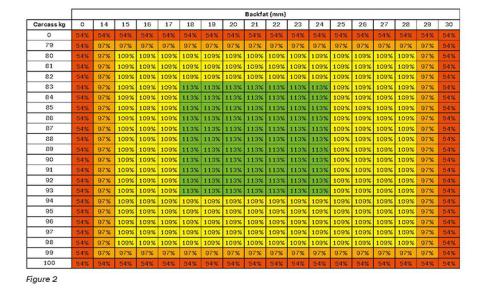

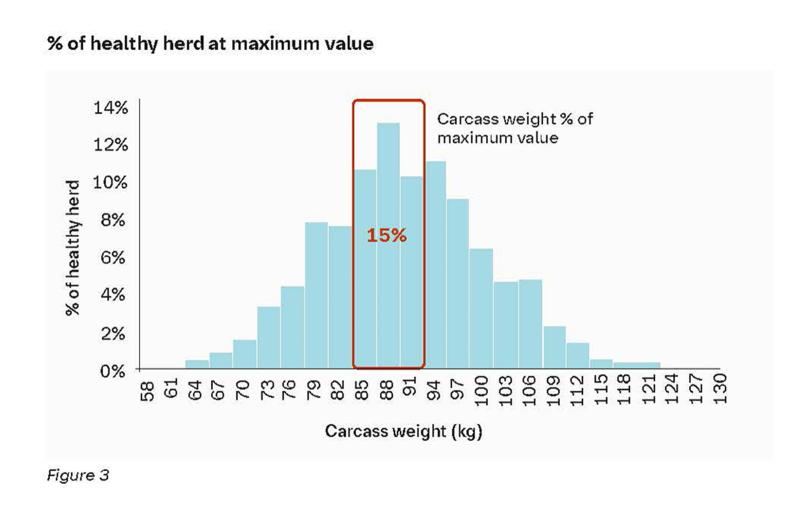

The second step in the adoption of precision agriculture is gaining an understanding of what exactly the farm is producing. This is a data‑oriented practice that is truly effective when the information is on an individual pig basis. On the breeding side of production this extends beyond individual sow data to information on weaned pig quality. Particularly how many weaned piglets fall below certain weight or quality standards. In finishing, individual pig data from the processor allows for the determination of how many pigs fall into the different matrix bins. As an example, Figure 2 shows a packer matrix where the maximum value is between 83 and 93 kg (carcass) and between 18 and 24 mm backfat depth. Figure 3 shows the weight distribution of a healthy herd from South Korea that has an average amount of variation. It also shows what percentage of those pigs achieved maximum value on the packer matrix shown in Figure 2.

Table 1 shows the total sale value produced by the group of 1000 head from Figure 3 as well as a hypothetical group of 1,000 head where all the pigs achieved maximum value (values shown in US$).

Difference in sales due to maximum value (Table 1).

| Average Herd | Hypothetical Herd | Additional Value |

Total Sales | $301,501 | $360,259 | $58,758 |

What this demonstrates is that if variation can be reduced, all while maintaining a similar cost of production, profitability would improve dramatically. While current technology renders such a decrease in variation prohibitive, even marginal reductions in variation can yield significant increases in profitability.

The ability of a production system to increase the value of each pig produced, all while without having to increase their production assets or costs, is where future profits will be extracted. Particularly when considering global competition and supply chain risk makes other avenues of increasing pig value more improbable in the coming years.

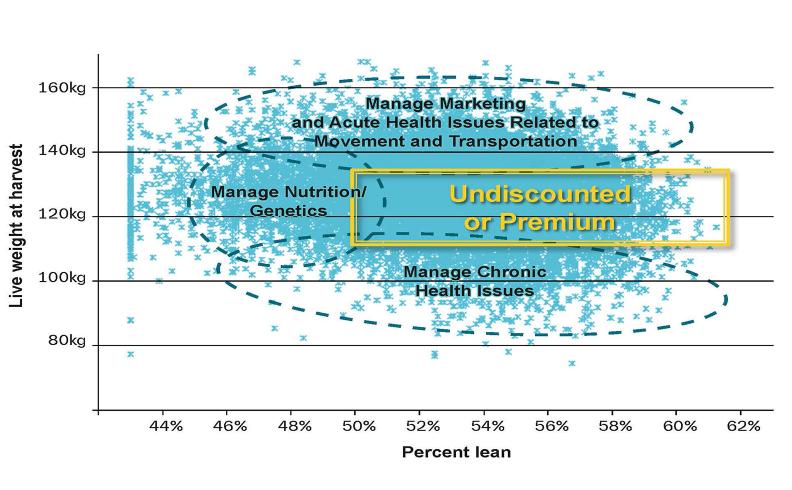

Figure 4 shows individual pig data from a US production system with feedback from production experts on the likely causes of why pigs had subpar performance. Two of the three primary causes of profit reducing variation are due to marketing and herd health. Identifying the causes of variation within a herd often reveals that simple, lowcost efforts, such as changing marketing practices, more effective disease management, or even vaccine choice can have major impacts on farm profitability. Additionally, if the individual pig data can be traced to individual flows, sites, or even barns, the level of precision intervention increases. Being able to target these interventions to where they are needed most helps reduce total cost significantly.

The need for precision agriculture practices becomes even more apparent in times of economic difficulties. Namely, when production costs are high and pig prices are low.

This is because these improvements are permanent in nature, meaning that when economic conditions improve, the farm is still operating at a much higher level of productivity. Making these changes is also important because it serves as the basis for adopting even more sophisticated precision methods and practices over time. However, all of this begins with being able to answer, “what exactly am I producing?”